Increase Efficiency: Just How Upgrading Undercarriage Parts Can Improve Performance

Wiki Article

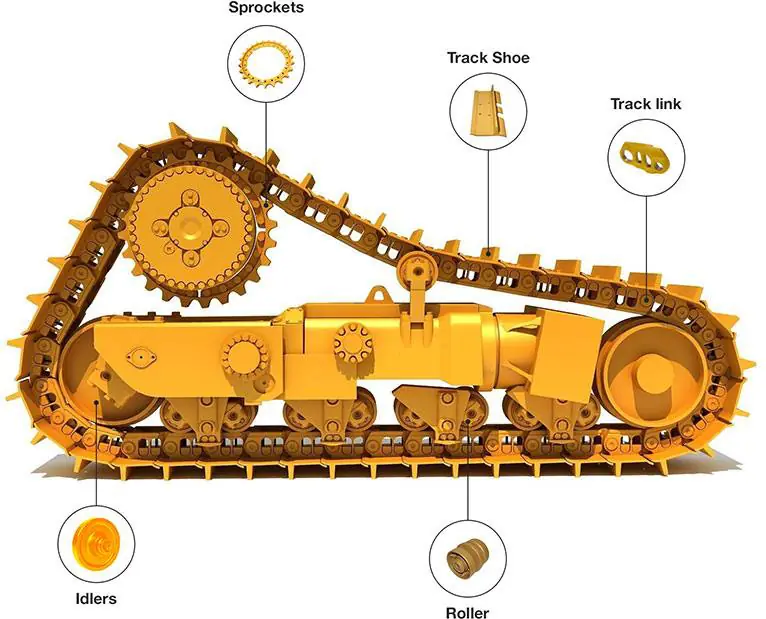

Discover Undercarriage Parts for Heavy Machinery

Recognizing the ins and outs of undercarriage components is important for the optimal performance and longevity of heavy machinery. From track footwear to idlers, gears, and rollers, each component plays an essential duty in the functionality of the devices. Looking into the specifics of these components unveils a world of precision design and longevity that maintains hefty equipment operating at its optimal. Remain tuned as we discover the value of undercarriage components and discover the maintenance methods that can improve the efficiency of these crucial elements.Relevance of Undercarriage Components

The undercarriage components of hefty machinery play an important duty in making sure the overall efficiency and long life of the equipment. These elements, consisting of tracks, rollers, gears, chains, and idlers, form the structure upon which the equipment runs. A properly maintained undercarriage not only offers stability and support to the heavy equipment but also contributes significantly to its operational efficiency and productivity.

Among the vital benefits of buying top quality undercarriage parts is the decrease of downtime and upkeep expenses. By utilizing durable components that can stand up to the roughness of sturdy applications, operators can reduce the need for frequent repair work and replacements, therefore taking full advantage of the maker's uptime and general lifespan.

Furthermore, appropriately working undercarriage parts guarantee optimal weight grip, maneuverability, and circulation, allowing the heavy equipment to operate smoothly even in tough terrains. This reliability is critical for sectors such as farming, building and construction, and mining, where tools performance straight influences job timelines and earnings. Finally, the importance of undercarriage components can not be overemphasized in maintaining the performance and durability of heavy equipment.

Sorts Of Track Shoes

When considering the different kinds of track shoes for hefty machinery, it is vital to examine their design and performance in relation to particular functional demands. Track footwear are vital components of the undercarriage system, giving security, traction, and weight circulation for heavy equipment such as excavators, bulldozers, and spider cranes.One of the most common kinds of track shoes consist of:

** Grouser Shoes **: Featuring raised metal bars (grousers) along the shoe's surface, these track footwear provide improved traction in challenging surfaces like mud, snow, and loosened gravel. undercarriage parts.

** Dual Grouser Shoes **: Similar to grouser shoes but with an additional collection of grousers, these track footwear supply also better grip and stability, making them suitable for incredibly rough surfaces.

** Three-way Grouser Shoes **: With three sets of grousers, these track shoes provide optimal traction and stability, making them suitable for the most requiring problems.

Selecting the best type of track shoe is vital for enhancing the performance and long life of heavy machinery while making certain security and efficiency throughout operations.

Function of Rollers and Idlers

Rollers and idlers play integral duties in supporting and leading the track shoes of hefty machinery during procedure. Rollers are cylindrical components that sustain the weight of the equipment and make certain smooth movement along the terrain. They help disperse the device's weight equally, reducing wear on the track footwear and minimizing vibrations. Idlers, on the More Bonuses other hand, guide the track chain and help keep appropriate stress. By protecting against excessive slack or tightness in the tracks, idlers add to the total security and performance of the machinery (undercarriage parts).Furthermore, rollers and idlers collaborate to keep the track shoes abreast, avoiding them from hindering or slipping off throughout procedure. Appropriately operating rollers and idlers are essential for ensuring the durability of the undercarriage system and optimizing the machine's performance. Normal upkeep and examination of these parts are necessary to determine any kind of signs of wear or damage early, preventing expensive repairs and downtime in the future.

Function of Sprockets in Machinery

Upkeep Tips for Undercarriage Components

Effective upkeep of undercarriage components is necessary for making sure the longevity and ideal performance of heavy equipment. Normal inspection of undercarriage components such as track chains, rollers, idlers, sprockets, and track footwear is critical to stop costly repair work and unforeseen failures. One vital maintenance tip is to keep the undercarriage clean from particles, mud, and various other contaminants that can accelerate wear and corrosion. It is likewise crucial to make certain appropriate track tension to avoid early endure parts. Greasing the undercarriage parts at recommended intervals helps to minimize rubbing and expand the life-span of the parts. Keeping an eye on for any kind of uncommon noises, resonances, or adjustments in machine efficiency can suggest possible problems with the undercarriage that call for prompt interest. By complying with these upkeep pointers carefully, heavy machinery operators can reduce downtime, reduce operating see here costs, and make the most of the efficiency of their devices.Conclusion

To conclude, the undercarriage parts of hefty equipment play an essential duty in making certain the smooth performance and durability of the look at more info equipment. Comprehending the importance of track footwear, idlers, rollers, and gears, along with carrying out correct maintenance techniques, can substantially impact the general efficiency and efficiency of the machinery (undercarriage parts). Normal inspection and timely substitute of damaged components are necessary in maximizing the life expectancy and performance of hefty machineryRollers and idlers play essential roles in supporting and assisting the track footwear of hefty equipment during procedure.In hefty equipment, gears offer a vital function in transferring power from the engine to the tracks, allowing the tools to relocate successfully and successfully. These parts are connected to the axles or final drives of the machinery and work in conjunction with the tracks to thrust the devices forward or backwards. Routine assessment of undercarriage components such as track chains, rollers, idlers, sprockets, and track footwear is crucial to avoid unforeseen malfunctions and expensive repair services. Understanding the value of track footwear, idlers, rollers, and sprockets, as well as applying correct upkeep methods, can substantially influence the overall efficiency and performance of the machinery.

Report this wiki page